Product and Services

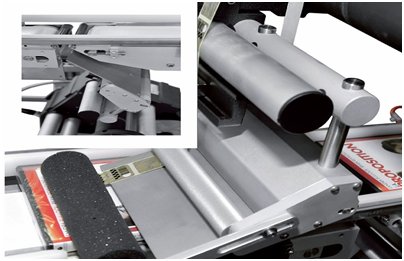

1. PRINT & APPLY LABELLERS (sub-section)

We offer 5 models of print & apply labellers

All Print & Apply Labellers are configured with SATO and Zebra thermal transfer print modules.

Real time printing.

All models are offered on a Left-Hand and Right-Hand version.

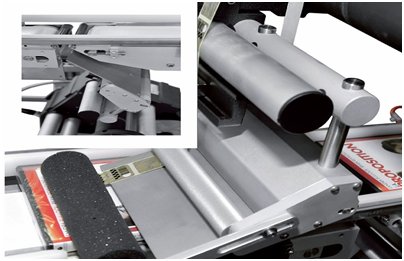

Labellers are equipped with synchronized dispense applicators or with pneumatic applicators for tamp and Reverse vacuum-blow labelling.

Labellers can be equipped with Plus control unit, featuring a graphic interface, allowing both label application and printing functions management and Inspector software for packaging validation.

If needed, we can also offer electro-pneumatic hot foil printers integrated with the Labellers.

Our PRINT & APPLY labellers are suitable for any product and industry. (Stainless steel and aluminium build components suitable for Pharmaceutical and Food Industry environment)

Supporting Stands are equipped casters and horizontal and vertical adjustments P & A Labellers guarantee performance and reliability under any critical production environment and heavy workloads.

POWERKIT series labellers, a normal Evolution 160 or 240 labeler can be equipped with a Sato or Zebra print module. Max Label width for printing purposes: 250mm

Bi-Fuel series

www.arca.it

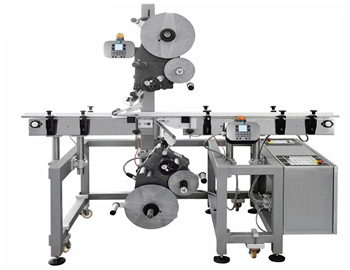

2. LABELLERS (sub-section)

We offer 5 model series of labellers for every need

"Dynamic" Series – (120mm / 4.72 in ) label liner maximum width. Speed: (40m/min – 131 ft/min). Max. label roll outside diameter: (260mm – 11 in).

"Easy" Series – (160mm / 6.30 in) label liner maximum width. Speed: (20m/min – 65.5 ft/min). Max. label roll outside diameter (360mm – 14.2 in).

"Evolution" Series - (160mm / 6.30 in) and (240mm / 9.5 in) label liner maximum width. Speed: (40m/min – 131 ft/min). Max. label roll outside diameter (360mm – 14.2 in).

Note: A normal Evolution 160 or 240 labeler can be equipped with a Sato or Zebra print module and becomes the ‘POWERKIT’ print & apply series labellers

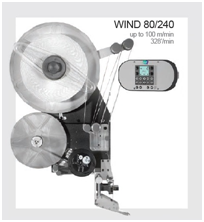

"Wind" Series - (80mm / 3.15 in) and (240mm / 9.5 in) label liner maximum width. Speed: (80m/min – 262 ft/min). Max. label roll outside diameter (380mm – 15 in).

"Flash" Series - (80mm / 3.15 in) label liner maximum width. Speed: (150m/min – aprox. 500 ft/min). Max. label roll outside diameter (380mm – 15 in).

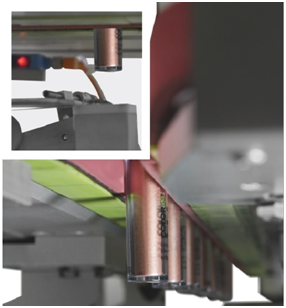

Labellers are equipped with synchronized dispense applicators or with pneumatic applicators for tamp and Reverse vacuum-blow or air blast labelling.

All of our labellers can be furnished with printing devices and are available in various widths.

We also offer electro-pneumatic hot foil printers integrated with the Labellers.

All models are offered on a Left-Hand and Right-Hand version.

Labellers are equipped with synchronized dispense applicators or with pneumatic applicators for tamp and Reverse vacuum-blow labelling.

Labellers can be equipped with Plus control unit, featuring a graphic interface, allowing both label application and printing functions management and Inspector software for packaging validation

The Control unit for FLASH series labellers, equipped with Touch screen, TFT graphic LCD colour display

Our Labellers are suitable for any product and industry. (Stainless steel and aluminium build components suitable for Pharmaceutical and Food Industry environment)

Supporting stands are equipped with casters and horizontal and vertical adjustments

Labellers guarantee performance and reliability under any critical production environment and heavy workloads.

3000 series

www.arca.it

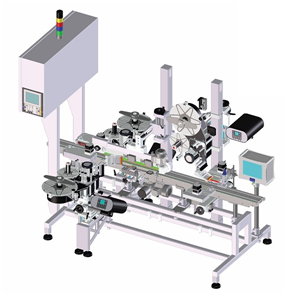

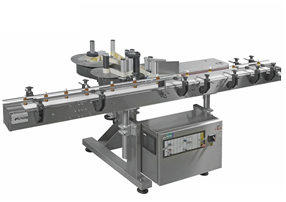

3. LABELLING SYSTEMS (sub-section)

We have solutions for any application and we have delivered hundreds of Custom designed labeling equipment including product handling systems integrated with existing customer lines

We offer 3 main flexible standard categories of Open Frame labeling systems/machinery, designed for in-line labelling of products with rectangular, square, elliptical or circular base (cylindrical and conical).

Extremely quick equipment set-ups.

Operational adjustments do not require the use of tools.

Depending on the application and label information required, all Labelling systems can be equipped with both labellers and Print & Apply labellers.

Models:

"LIGHT" (for applying 1 label)

"SOLID" (for applying up to 2 labels)

"SKYTECH" (for applying from 1 to 4 labels) for largest scale production

We also offer:

"STRIPED LINERLESS" ( A system for ecological labelling of tubs and parallelepiped products. Allows for application on the upper surface, sides and base of the product )

"CARD BOARD "( A system for labeling and coding flat products: laid down packets (either already glued or still “open”), telephone and credit cards, membership cards, envelopes, hang tags for clothing, etc.)

"PHARMATRACK"( A system for coding and labeling pharmaceutical packets. It allows for application on the upper surface of the product )

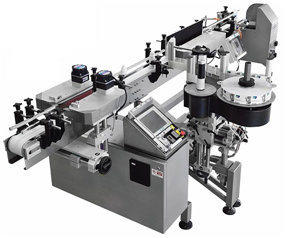

3.1 SOLID SERIES SYSTEMS and APPLICATIONS

Steel finish with Evolution 160 labeller and product spacing module

Wrap around and product handling system shown

Steel finish with Evolution 160 labeller and upper stabilizer

Side labeling and product handling system shown

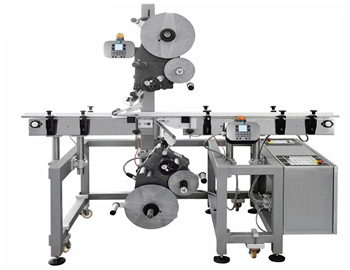

Steel finish with (2) Evolution 160 labellers

Two Side labeling and product handling system shown

Steel finish with (2) Evolution 160 labellers

Top and Bottom labeling and product handling system shown

Steel finish with Evolution 160 labeller and graphic interface

Bottom labeling and product handling system shown

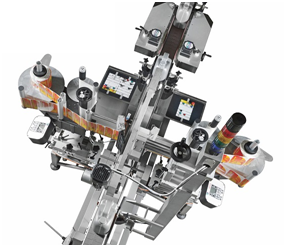

Steel finish with 3 Wind 80 labellers and 2 side L-Seal adapters

Top labeling and Two side Top labeling system shown

3.2 LIGHT SERIES SYSTEMS and APPLICATIONS

Steel finish with Easy 160 labeller

‘Top Labelling on product with Convex Profile’ and product handling system shown

Steel finish with Easy 160 labeller

‘Top Labelling on product with Critical surfaces’ and product handling system shown

Steel finish with Easy 160 labeller

“Top Labelling on a light product’ and product handling system shown

Steel finish with (2) Evolution 160 labellers

Top and Bottom labeling and product handling system shown

Steel finish with Evolution 160 labeller adapted to Print & Apply PowerKIT

Bottom labeling and product handling system shown

Steel finish with 3 Wind 80 labellers and 2 side L-Seal adapters

‘C-wrapping/fold top labelling’ system shown

Steel finish Conveyor with Idle Rollers

‘Labelling on cylindrical and unstable products’ system shown

Steel finish with Evolution labeller

‘Wrap side labelling’ system shown

Steel finish with Evolution labeller

‘Package side labelling’ system shown

3.3 ‘STRIPED LINERLESS’ SYSTEMS and APPLICATIONS

System for the ecological labelling of tubs and parallelepiped products. It allows for application on the upper surface, sides and base of the product.

The limited thickness of the Linerless material, free of silicon liner, and the “short step” advancement allows the use of bigger label rolls and consequently significant operative duration.

The thermal transfer digital coder allows for printing alphanumerical characters and barcodes.

It’s provided with its own touch screen control unit (it doesn’t require connection to PC).

It can be connected/linked to a set of scales for printing of variable weights

Ergonomically positioned adjustments and ergonomically positioned control panel with graphic display.

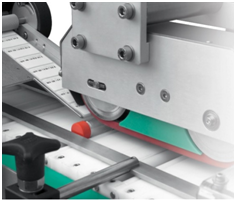

3.4 ‘CARD BOARD’ SYSTEMS and APPLICATIONS

A system for labelling and coding flat products: laid down packets (either already glued or still “open”), telephone and credit cards, membership cards, envelopes, hang tags for clothing, etc.)

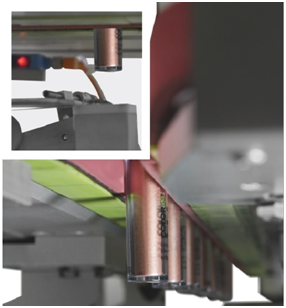

Provided with an ink jet print module of thermo graphic type (HP technology); up to 4 (four) print heads

Provided with code scanners, sensors, vision systems with camera for checking label presence, label info and printed data.

Ergonomically positioned adjustments and ergonomically positioned control panel with graphic display

3.5 ‘PHARMATRACK’ SYSTEMS and APPLICATIONS

A system for coding and labelling pharmaceutical packets. It allows for application on the upper surface of the product system for labelling and coding flat products.

Provided with up to 3 thermo graphic ink jet printing modules (HP technology), for upper or lateral coding.

Provided with code scanners, sensors, vision systems with camera for checking label presence, label info and printed data.

Provided with traceability software

Ergonomically positioned adjustments and ergonomically positioned control panel with graphic display

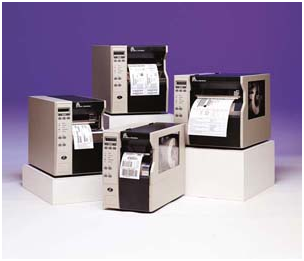

4. DESKTOP SYSTEMS (sub-section)

We offer different models of desktop printers:

Zebra Xi Series

SATO M84 Pro

SATO CL400e / SATO CL600e

www.arca.it

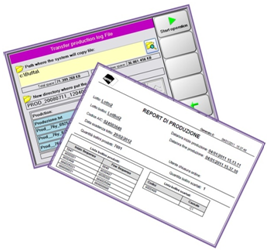

5. SOFTWARE (sub-section)

ArcaLOG software

Logistic software:

Print management

Unattended labelling

Traceability of products and shipments

Packaging validation

Arcalog is a “suite” of programs specially designed for production environments and industrial logistics. These standard software applications are easily integratable and compatible with Sato, Zebra, Videojet printers and with the most common digital print devices (thermal transfer, inkjet and laser).

Customizable and compliant to multinational contexts, thanks to a multilingual user interface

LabelPRINTER and CHANGE

The LABEL PRINTER software allows users to create graphic layouts and print labels.

All PRINT ONLY functions can be guided and controlled through a customized interface, created by Arca on request based on specific production needs

Its PRINT ONLY module allows the operator to effectively control all print functions: select label graphics, check them in preview, fill out the variable fields, or launch printing on a connected device.

All PRINT ONLY functions can be guided and controlled through a customized interface, created by Arca on request based on specific production needs.

UNMANNED PRINTING

The CHANGE software identifies and updates graphics to be printed, without the operator having to intervene (unmanned printing).For example, it can automatically update the number of batches based on the PC’s clock.

CHANGE updates graphics created with the LABEL PRINTER and it can also be integrated into labelling system graphic interfaces.

LABEL MANAGEMENT

The LABEL MANAGEMENT software identifies and updates graphics to be printed,the program features an interactive user interface for:

line control

alarm display

checking the status of the connected devices

the starting and the suspending production;

The monitoring module, for each production batch, provides a wealth of information including:

number of printed or applied labels

traceability of errors

traceability of operators

event times

Manages and retrieves information from multiple devices including code scanners for product validation PLC and scales. Allows for differentiated usage (based on programmed logics) of various print devices for conditioned labeling and/or at different points on the product.

The SLIM version is installable on an INSPECTOR control unit and on board all Arca labelling systems equipped with a graphic.

TRACKING

The TRACKING software includes all functions in the Label Management program.

In addition, it allows for complete multilevel traceability of production.

Or better still, the recording of unambiguous identification codes of unit and/or multiple packages (bundles, boxes or pallets) for each lot. TRACKINGTracking also allows for the traceability of batches of raw materials used in production.

The TRACKING PHARMA version is specifically designed for managing multilevel traceability in pharmaceutical environments.

TRACKING and TRACKING PHARMA are also available in the SLIM version, for mono-level traceability (usually unit packages only) and reconciliation, are installable on an INSPECTOR control unit and on board all Arca labeling systems equipped with a graphic interface.

VISUAL WAREHOUSE

The VISUAL WAREHOUSE software allows for the allocation of packages, even automatically, with a graphic representation of the warehouse layout and the status of each location

It can manage warehouse loading according to a “chaotic” mode (for the optimization of spaces) or by type of goods or other customizable logics.

It can manage the unloading of each location with FIFO/LIFO criteria or by specific commission.

VISUAL WAREHOUSE is complementary to the Tracking (loading) and Delivery (unloading) programs.

CODE VERIFY & CODE VERIFY INSPECTOR

Competitive markets impose increasingly greater productivity.

The growing variety of products (formats, versions, fragrances, flavors, etc) increases the number of packagings managed.

Ongoing changes to graphics, linked to promotions and constantly evolving legislation, further complicate matters on the packaging line.

In such a complex scenario, production is subject to a multitude of risks:

Unreadable barcodes/2D codes

Mix ups of unit packages

"Logistical" mix ups

The most effective and economic solution is to automatically check 100% of the packages

during production, inspecting all barcodes/ 2D codes for:

CODE VERIFY & INSPECTOR

The Code Verification software, installed on an Inspector control unit, is the most advanced solution for managing barcode and 2D code scanners:

1) code readability check

2) conformity check of the code read

3) analysis of the grade of readability

4) check of conformity of the code read to a family of preset codes

5) management of a possible product ejector

6) display of hardware alarm conditions

7) possibility of setting up to 5 conventional print quality ranges

8) possibility of setting the activation of alarms and advance alarms, in relation to preset limits

9) graphic display

10) graphic representation of the barcode’s actual positioning on the product

11) graphic representation of the barcode’s actual positioning on the product

12) management of the barcode scanner’s parameterization

13) recording of readings and important production data

www.arca.it